Applications of Virtual Reality in Industrial Engineering Education

Enhancing production efficiency is a shared aspiration among businesses. For this, they are in constant need of skilled professionals who can scrutinize existing systems and institute strategic enhancements.

Among these professionals, industrial engineers stand out as the best option for organizational optimization.

Industrial engineers know how to make or do things better, streamline processes, manage resources, and drive innovation.

As the demand for these versatile professionals continues to grow, so does the need for innovative educational approaches that can prepare them for the challenges of an ever-evolving industrial landscape.

In the present educational world, virtual reality has the excellence to teach industrial engineering to budding students.

In this blog, we will explore the applications of Virtual Reality in industrial engineering education. So, let’s begin

Virtual Reality in Industrial Engineering Education

From virtual factory tours to collaborative learning environments, here are some of the benefits of virtual reality in industrial engineering education.

✔️ Virtual Factory Tours

With the traditional educational approach in industrial engineering education, educators constantly struggle to equip students with the necessary skills and hands-on experience in the industrial setup.

The value of firsthand experience cannot be overstated, especially in fields like industrial engineering where tactile knowledge is as crucial as theoretical understanding.

Industrial engineering, with its emphasis on optimizing engineering processes and systems, demands a practical understanding of how things work in a real manufacturing facility. However, the geographical dispersion of industries and the logistical challenges associated with physical tours often restrict students' exposure to diverse industrial environments.

Conversely, virtual reality in engineering education, not only addresses this challenge but also affects how we impart knowledge to future industrial engineers.

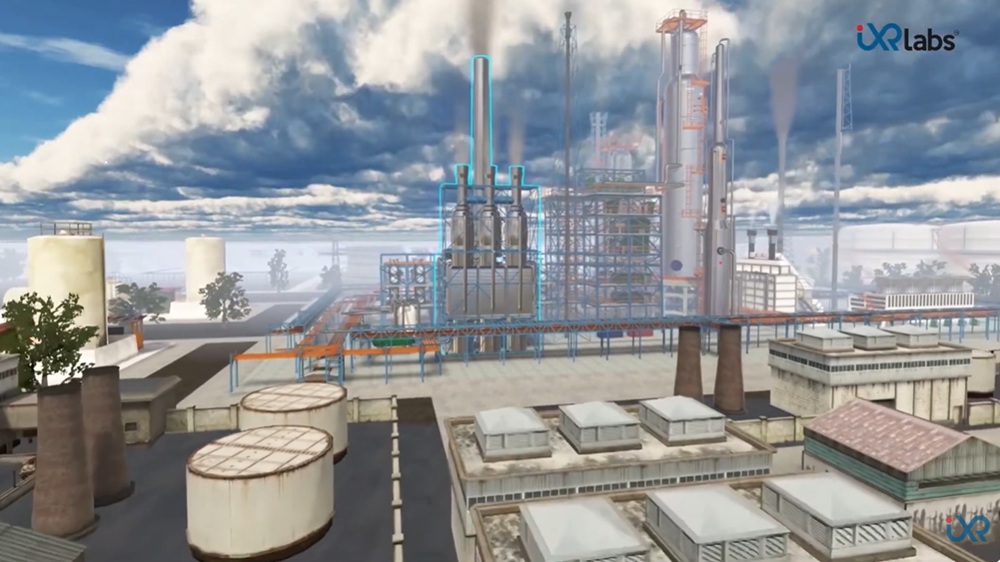

Virtual reality factory tours in the VR world offers an opportunity for the student to find themselves transported into meticulously replicated virtual manufacturing facilities with few gestures.

By wearing VR headsets, they can engage with machinery, observe production flows, and understand the intricacies of different manufacturing processes in a highly interactive and immersive manner.

Within VR technology, all the constraints of a traditional factory tour, from the size of the factory to the associated costs, evaporate and students are allowed to gain practical experience without leaving their seats.

✔️ Simulation-Based Learning

Simulation-based learning has long been a fundamental aspect of industrial engineering education. However, the traditional approach to simulations often falls short of delivering the immersive and risk-free experiences that VR can offer.

Virtual reality simulations for industrial engineering education ship students meticulously crafted virtual scenarios that mirror the complexities of real-world industrial processes.

Well, in the traditional classroom setting students may learn about the theoretical concepts in detail but the true test lies in applying those concepts in practical situations.

If educators teach engineering through modern tech like virtual reality, they can offer students a safe and controlled virtual environment where they can delve into the intricacies of the industrial setup.

In this setup, the students can explore the industries without any fear of making mistakes or causing disruptions and gain hands-on experience similar to the actual work setup.

Additionally, whether it involves streamlining production lines, orchestrating efficient supply chain management, or troubleshooting machinery glitches, VR simulations provide an unbeatable platform for students to experiment without real-world consequences.

This not only nurtures a deeper understanding of theoretical principles but also cultivates a level of confidence that can only be attained through hands-on experience.

✔️ Interactive Design and Prototyping

In industrial engineering, where innovation is key, the stages of design and prototyping play a pivotal role in bringing ideas to fruition.

VR technology empowers budding engineers to transcend the limitations of traditional 2D sketches and CAD models.

Through immersive 3D modelling, students can step inside their designs, and manipulate them in real time within a virtual environment.

This hands-on approach not only enhances their spatial awareness but also cultivates a profound connection between the engineer and the virtual prototype.

Moreover, it is true to say that the early stages of product development are filled with challenges, and identifying potential flaws is highly crucial.

With Virtual reality simulations, the students are allied to facilitate a comprehensive examination of virtual prototypes, allowing students to scrutinize every detail. We can say that VR improve engineering product design.

This ability to detect and rectify issues at the virtual stage saves time and resources in the actual manufacturing process.

Another important aspect is that when students are allowed to manipulate and interact with virtual prototypes, it accelerates their learning curve.

"Accelerate your Industrial Engineering Education with Virtual Reality - Immerse yourself in cutting-edge technology for an unparalleled learning experience"

✔️ Collaborative Learning Environments

Engineering processes are complex and hence, they often require effective collaboration and teamwork.

However, the traditional educational setup, because of its physical limitations, restricts the students from coming together and working in harmony with each other on a single project.

For all that virtual reality is the right catalyst.

Through virtual meeting spaces, students are no longer bound by the physical constraints of a classroom. Instead, they can seamlessly connect in a shared virtual environment, fostering teamwork, idea exchange, and joint problem-solving.

With VR industrial engineering education, the classroom becomes a playground for creativity, where students from different corners of the world converge to contribute their unique perspectives to industrial engineering projects.

Its significance extends beyond the classroom, mirroring the collaborative nature of real-world industrial projects.

It allows students to step into the shoes of the engineers, designers, and project managers who must seamlessly work together in the industrial setup.

By engaging in collaborative VR environments during their education, students gain not only technical skills but also invaluable experience in navigating the complexities of teamwork.

✔️ Remote Internships and Experiential Learning

Traditionally bound by geographical constraints, internships are now breaking free from these limitations, all because of the integration of VR into education.

Remote internships facilitated by VR technology provide students with unprecedented global opportunities for hands-on experience. Now students are no longer confined to a specific location.

Instead, students can seamlessly connect to industrial facilities from the comfort of their classrooms.

Thus, allowing them to actively participate in live projects, interact with professionals in the field, and gain practical insights into the intricacies of industrial engineering.

Well, it is noteworthy that the significance of this innovation extends beyond convenience. It is a preparation for the demands of a globalized workforce.

As the business landscape becomes increasingly interconnected, the ability to collaborate remotely is a skill set that holds immense value.

VR-enabled remote internships not only expose students to diverse industrial practices but also instil in them the adaptability and resilience required in a world where physical boundaries are no longer barriers to collaboration.

Precisely, VR internships broaden the scope of education, offering students a glimpse into different industrial contexts, practices, and challenges.

Get the App from Meta Store: Download Now

Get the App from Meta Store: Download Now

✔️ Real-Time Data Visualization

In industrial engineering education, the power of data cannot be overstated. The ability to analyze, interpret, and derive meaningful insights from complex datasets is a fundamental skill for aspiring industrial engineers.

In this regard, innovative technologies like VR and AR help engineering students by creating an immersive environment where students can dive into real-time data scenarios, bringing abstract numbers to life.

Whether it's monitoring production metrics on a bustling factory floor, scrutinizing the intricacies of supply chain data, or fine-tuning workflow efficiency, VR provides a dynamic and interactive platform for students to engage with data in unprecedented ways.

The traditional approach of studying data through charts and graphs is replaced by an experiential journey where students can navigate through three-dimensional representations of data landscapes.

This not only enhances their understanding of the data but also cultivates a holistic view of how different variables interact in an industrial setting.

Moreover, the real-time aspect of VR data visualization adds a layer of complexity and urgency, mirroring the fast-paced nature of industrial operations.

This means that students are not merely observers of the knowledge. They are active participants in the decision-making process, responding to changing data dynamics on the fly.

Overcoming Challenges and Future of Virtual Reality in Education

The integration of Virtual Reality (VR) into industrial engineering education has not been without its challenges.

The hurdles of cost, accessibility, and the requirement for specialized equipment have been significant roadblocks for a lot of educational institutions that are looking to adopt Virtual Reality as a teaching tool.

However, the future prospects of VR in industrial engineering education are quite promising. The ongoing technological advancements are setting new ways to overcome these challenges.

As the cost of VR hardware decreases and more affordable options become available, the financial barrier that once hindered widespread adoption is gradually diminishing.

Moreover, improvements in accessibility, including cloud-based VR solutions, are making it easier for educational institutions around the world to integrate VR into their curricula.

The need for specialized equipment is also being addressed through innovations that make VR more adaptable to existing classroom setups.

As VR hardware becomes more streamlined and user-friendly, institutions can envision a future where students can engage with VR experiences using standard devices, further reducing the barriers to entry.

Also, engineering colleges consider VR lab. It is one of the most effective ways that can reduce setup and maintenance costs.

Conclusion

To conclude, the application of virtual reality is not only restricted to entertainment. It has impacted engineering education tremendously.

From virtual factory tours to collaborative learning environments, the applications of VR in industrial engineering education are diverse and unmatched.

In this changing educational world, adopting such innovative technologies is no longer a matter of choice, instead, it has become a necessity. Engineering institutions must adopt this tool to teach the next generation of engineers.

.png)